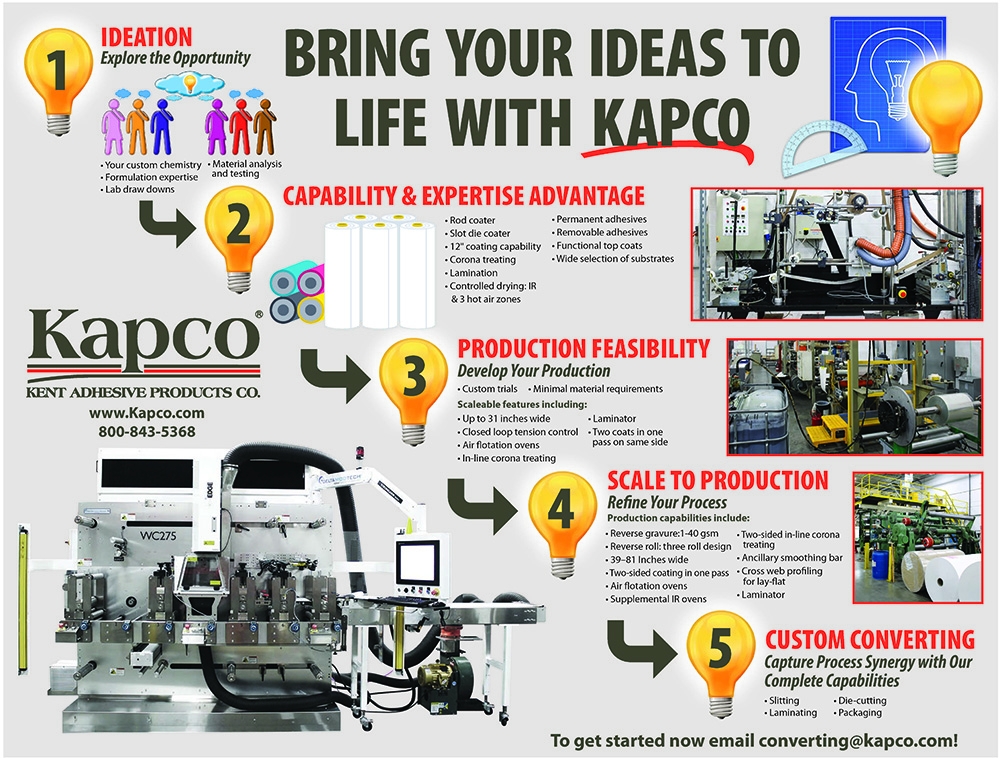

Product Development

Decades of Experience Combined with State of the Art Technology

Process capabilities that combine custom coating and various converting technologies including coating, laminating, rotary die and laser cutting.

- Small center cut and slug removal

- No tooling for small quantities

- Tight tolerances; up to +/- 0.005”

- Lab coater for proof of concept

- Part identification

- Optimized process that reduces production time

- Island placement of material

- Continuous web coating from 12" to 81"

- Pattern Coating

- Flat-bed Precision Cutting of Large Parts

- Packaging

- Appliance

- Automotive

- Medical

- Electronics

- Energy

Your New Competitive Edge:

A Market Partner To Help You Take Your Idea from Prototype to Production

Our Custom Converting expertise gives you in-depth knowledge using a wide range of materials, including exotic and high performing products. Additionally, our advanced coating and converting capabilities allow us to achieve:

- Extremely Complex Constructions

- High Speed Production with Low Waste

- Totally Unique End-Use Products

It's why more customers say …

"Before coming to Kapco, we had no idea you could make materials like this."Materials & Components Commonly Used

Adhesives

- Permanent

- Removable

- Repositionable

- Pigmented

- Microsphere

- Water Soluble

- Heat Activated

- Water Activated

Functional & Decorative Topcoatings

- Inkjet

- Laser

- Indigo

- Blockout

- Thermal

- UV Ink Receptive

Substrates and Specialty Constructions

- Vinyl

- PET

- BOPP

- Spun Bond

- OPP

- HDPE

- Grafoil-Graphite Paper

- 100% Cotton Rag

- Crisper

- Synthetic Paper

- Destructible Vinyl

- Holographic

- Acrylic Films

- Acetate

- Tyvek®

- Foams

- Valeron®

- Teslin®

- Non-Wovens

- Polyimide Film

- Permanent Laminations

- Multi-Ply

- Rag Paper/Poly/Rag Paper

- Void/Security Coatings with Taggants

- Digital/Wide Format